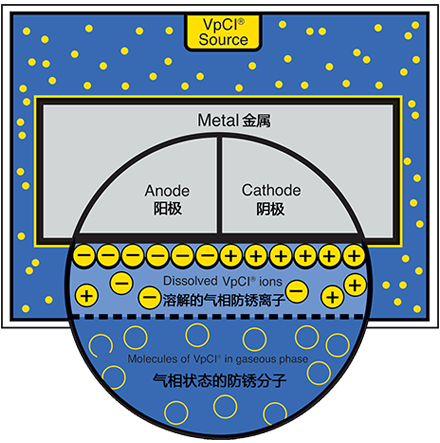

Qingdao Cortec Rust Proof Materials Co., Ltd., is authorized by the United States CORTEC corporation, China's exclusive distributor, our company's main products are VpCI (vapor phase) series of corrosion-proof products, main features are: with contact corrosion-proof and non-contact corrosion-proof double protection.

Cortec company is in the field of VpCI rust prevention, has been more than 40 years of history of corrosion-proof products. At present, all products have been Certified by ISO9001 and ISO14000, some products meet the United States military supplies standards and the United States FDA ("U.S. Food and Drug Administration") recognized......

產(chǎn)品與服務(wù)

All Product

-

VpCI-277

-

VpCI-369 Open Atmosphere Removable Coating

-

VpCI-329D

-

VpCI-326

-

VpCI-322 Oil Concentrate

-

M-531 Oil Based Corrosion Inhibitor

-

VpCI-Super Penetrant

-

M-529 Oil Based Corrosion Inhibitor

-

VpCI-377 water-based concentrate

-

VpCI-337 waterborne corrosion inhibitor

-

VpCI-379 water-based liquid

-

BioCorr Rust Preventative

-

VpCI-423 water-based gel

-

VpCI-418LM Heavy Duty Alkaline Cleaners

-

VpCI-417 heavy-duty cleaner

-

VpCI-422 Rust Remover

-

Corwipe500

-

VpCI-414 cleaner

-

VpCI-126HP UV shrink film

-

VpCI-126 Blue zip lock bag

-

Cor-Pak Tablets

-

VpCI-144/146 Paper

-

VpCI-126 Blue sheet

-

Cor-Pak VpCI Stretch Film

-

VpCI-609Biodegradable Powders

-

VpCI-609S Biodegradable Powders

-

VpCI-309 VpCI Powder for Ferrous Metals

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:qkvkrai.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:qkvkrai.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  合作客戶

合作客戶  cortec power of attorney

cortec power of attorney

ISO 17025

ISO 17025

ISO 9001

ISO 9001

2017-2018 #3 Sales Distributor ASIA-PACIFIC

2017-2018 #3 Sales Distributor ASIA-PACIFIC

Mr. Zhu took a photo with Christie CORTEC USA

Mr. Zhu took a photo with Christie CORTEC USA

Mr. Zhu took a photo with Mr. Boris, founder of CORTEC

Mr. Zhu took a photo with Mr. Boris, founder of CORTEC

Mr. Zhu was invited to attend the 40th anniversary celebration of CORTEC

Mr. Zhu was invited to attend the 40th anniversary celebration of CORTEC

GM Zhu took a photo with Academician Hou Baorong

GM Zhu took a photo with Academician Hou Baorong