Service Hotline

Service Hotline

MCI-2005

市 場 價(jià):¥0

優(yōu) 惠 價(jià):¥1

庫 存:0

PRODUCT DESCRIPTION:

MCI®-2005 is a water-based, organic, corrosion inhibiting admixture for protection of metallic reinforcement in concrete structures.

E-Mail:zzgvci@163.com

商品詳細(xì)

When incorporated into concrete, MCI-2005® forms a protective, monomolecular layer on embedded metals that inhibits corrosion. In new construction, this is quantified by an increase in critical chloride threshold and subsequent reduction in corrosion rates when corrosion does initiate. When used with repair mortars and grouts, MCI®-2005 not only protects rebar within the patch, it is able to migrate into undisturbed concrete adjacent to the repair, to protect reinforcement already in place.

MCI®-2005 has been awarded the USA BioPr efer r ed? designation (www.biopreferred. gov).

PACKAGING & STORAGE

Available in 5 gallon (19 Liter)

pails, 55 gallon (208 Liter) drums,

and 275 gallon (1040 Liter) totes.

Store away from direct sunlight and at ambient temperatures – above 32?F (0?C) and up to 131?F (55?C). When properly stored, MCI®-2005 has a shelf life of 24 months.

HOW IT WORKS

MCI®-2005 is an organic corrosion inhibitor. It is considered ambiodic (mixed), meaning it protects both anodic and cathodic areas within a corrosion cell. MCI®- 2005 contains a blend of amine salts of carboxylic acids which form a protective layer on embedded reinforcement delaying the onset of corrosion as well as reducing existing corrosion rates.

MCI®-2005 is effective at enhancing the durability and extending the service life of concrete structures exposed to corrosive environments (carbonation, chlorides, and atmospheric attack).

WHERE TO USE

?Reinforced concrete including precast, pre-stressed, and post-tensioned structures

?Corrosive environments including exposure to deicing salts, saline groundwater, airborne chlorides, and carbonation

?Marine and coastal structures, highways and bridges, parking decks, balconies, pools, concrete tanks, pilings, substructures, piers, pillars, pipes, and utility poles

ADVANTAGES

?Biobased (67%), awarded USA BioPreferred? designation (www.biopreferred.gov)

?Earns credit towards LEED certification

?Lower toxicity and environmental impact than traditional corrosion inhibiting admixtures such as calcium nitrite

?Low dosage rate with minimal effect on concrete properties (i.e. workability, strength development, air entrainment, etc.)

?Single dosage rate which is independent of expected exposure to chlorides

?Ability to migrate through porous substrates (concrete, masonry, limestone, etc.) by capillary action, vapor diffusion and ionic attraction

?Meets all requirements of ASTM C1582

?Certified to meet ANSI/NSF Standard 61 for use on structures holding potable water

?Field and lab tested worldwide

Complies with CSA S413, Section C1.2, for corrosion inhibiting

PHYSICAL PROPERTIES

|

Appearance |

Clear dark brown liquid |

|

pH |

9.5-11.5 (neat) |

|

Non-volatile Content |

44-55% |

|

Density |

9.5-10.3 lb/gal (1.14-1.23 Kg/L) |

|

Shelf Life |

24 months |

DOSAGE

Add MCI®-2005 to concrete mix or repair mortars at 1 pt/yd3 (0.6 L/m3). Dosage is fixed and independent of chloride levels.

APPLICATION

MCI®-2005 is best added with the mix water into ready mix concrete at the plant. Alternatively, it can be dosed into the ready mix truck using portable dosing equipment. Concrete should be mixed thoroughly before placement.

STANDARD TEST RESULTS

|

Slump |

ASTM C143 |

Neutral |

|

Air Content |

ASTM C231 |

Neutral |

|

Density |

ASTM C138 |

Neutral |

|

Set Time |

ASTM C403 |

Delayed |

|

Flexural Strength |

ASTM C78 |

Improved |

|

Compressive Strength |

ASTM C192 |

Improved |

|

Corrosion Properties |

ASTM C1582 ASTM G180 |

Meets Requirements |

|

Biobased Content |

ASTM D6866 |

67% |

|

Workability |

N/A |

No adverse effects when used with pozzolans or other high performance concrete admixtures |

|

ASTM C1582 PHYSICAL PROPERTY RESULTS |

|||||

|

Setting Time |

|||||

|

|

Control |

MCI 2005 |

Relative to Control |

ASTM C1582 Requirement |

Result |

|

Initial Set (Minutes) |

312 |

431 |

+119 |

+/- 210 Min of Control |

Meets Requirement |

|

Final Set (Minutes) |

404 |

524 |

+120 |

+/- 210 Min of Control |

Meets Requirement |

|

Compressive Strength |

|||||

|

3 Day (psi) |

3290 |

3647 |

111% |

Min 80% of Control |

Meets Requirement |

|

7 Day (psi) |

4070 |

4377 |

108% |

Min 80% of Control |

Meets Requirement |

|

28 Day (psi) |

5143 |

5330 |

104% |

Min 80% of Control |

Meets Requirement |

|

6 Month (psi) |

6077 |

6650 |

109% |

Min 80% of Control |

Meets Requirement |

|

1 Year (psi) |

6463 |

6877 |

106% |

Min 80% of Control |

Meets Requirement |

|

Flexural Strength |

|||||

|

3 Day (psi) |

585 |

591 |

101% |

Min 80% of Control |

Meets Requirement |

|

7 Day (psi) |

661 |

691 |

104% |

Min 80% of Control |

Meets Requirement |

|

28 Day (psi) |

757 |

797 |

105% |

Min 80% of Control |

Meets Requirement |

|

Shrinkage |

|||||

|

Length Change (%) |

-0.025 |

-0.021 |

0.004 |

Max 0.010 Over Control |

Meets Requirement |

|

Durability |

|||||

|

Freeze/Thaw Durability |

99.1 |

98.8 |

99.8 |

RDF 80% |

Meets Requirement |

|

ASTM C1582 CORROSION PROPERTIES - ASTM G180 RESULTS |

||||||||||

|

Sample |

Potential |

Rp |

1/Rp |

Log (1/Rp) |

Area (cm2) |

Dosage |

Mean 1/Rp |

SD 1/Rp |

Log (1/Rp) |

Log SD |

|

mV (SSC) |

(Ohms) |

(μS/cm2) |

(L/m3) |

(μS/cm2) |

(μS/cm2) |

|||||

|

Cortec®-1 |

-509 |

8192 |

23.85 |

1.38 |

5.12 |

0.60 |

38.91 |

21.29 |

1.33 |

0.29 |

|

Cortec®-2 |

-530.6 |

3626 |

53.96 |

1.73 |

5.11 |

|||||

|

Cortec®-3 |

-500.2 |

9373 |

20.85 |

1.32 |

5.12 |

|||||

|

Cortec®-4 |

-457.9 |

24360 |

8.10 |

0.91 |

5.07 |

|||||

|

Controls (13) Average of Results |

-522.9 Average |

|

0 |

394.71 |

214.21 |

2.49 |

0.35 |

|||

The results from the inhibitor tests were compared to 13 control runs on the same steel heat, and using the same cement in lab database. The comparsison shows that MCI®-2005 reduces the corro- sion current (1/Rp) by a factor of ten so it meets the ASTM C1582 requirement of being 1/8 the value (49.3μS/cm2) of the control specimens without inhibitor.

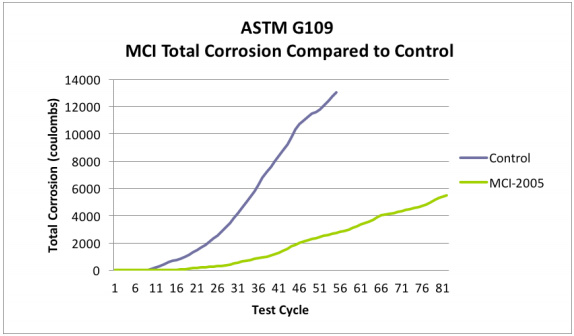

ASTM G109 RESULTS

ASTM G109 - Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments

MCI®-2005 doubles the time to the onset of corrosion and reduces corrosion currents by 80% compared to untreated samples.

CONSIDERATIONS

The use of MCI®-2005 can cause a delay of initial setting time. The extent of this delay is dependent on the mix design, temperature and humidity. The combination of MCI®-2005 with certain superplasticizers can also increase the set delay experienced. Concrete properties are always best determined in a trial using the actual mix components. Cortec recommends a trial batch anytime you are using MCI®-2005 with new mix components.

Consult with Cortec’s Technic

Qingdao Cortec Rust Proof Materials Co., Ltd.,

Consultation hotline:0532-80989502

Sales Hotline:135-0535-2885

E-mail:zzgvci@163.com

QQ:592192408

Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

Alibaba store:https://shop1420649126784.1688.com

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:qkvkrai.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:qkvkrai.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone